Do you have any plans to sell product packaging? If so, there are many things to consider and learn about Packaging Box. One of the most crucial things to consider now is selecting suitable packaging materials.

What are the types of packaging Boxes?

Chipboard Packaging

Electronics, healthcare, cosmetics, and food and beverage products are specific industries that employ chipboard packaging. These boxes are manufactured from recycled paper stock and are simple to fold and cut. These boxes are an additional inexpensive packaging choice for your goods. thePackagingPro has further details regarding package boxes.

Chipboard sheets are made of low- or high-density materials, which vary in their densities and strengths. The sheet will need to be treated with bleach sulfate and Clay Coated News Back if you wish to print an image on the chipboard. Notably, this procedure increases the durability of the chipboard sheets.

Chipboard boxes are lightweight, so if you deal with heavier things, you might not want to use them. They are designed for supermarket products like crackers, tissue boxes, and cereal. Additionally, if you keep your goods in a damp atmosphere, the packages may quickly weaken, expand, or become discolored.

Corrugated Boxes

An essential component of the packaging sector is corrugated boxes. Corrugated boxes have been a standard form of packaging for decades. On packaging lines throughout the world, they are utilized for packaging a tonne of different items.

It’s common to buy corrugated boxes already performed into the classic rectangular box shape. Alternatively, they can show up as flat stacks, where the boxes need to be assembled by hand. https://thepackagingpro.com specializes in packaging boxes.

Case erectors are frequently used in conjunction with corrugated boxes for packing purposes. The machinery used for packing includes case erectors. People use these devices to mold flat cardboard into conventional box shapes. The things are subsequently packaged and shipped using the boxes.

Paperboard Boxes

Paperboard is a durable yet lightweight material used to make paperboard boxes. The paperboard sheet is simple to cut and mold into any unique building or form. Because of these qualities, these boxes are the finest choice for customized packaging.

Paperboard sheets are produced from fibrous materials such as wood or recovered waste paper from the bleaching process. The paperboard boxes are available in various grades to meet the different packaging needs.

These custom printed boxes can package frozen food, milk, juice, cosmetics, medications, and other items. These boxes are the ideal choice for frozen goods and other food-related products since they are less moisture-resistant. Your paperboard packaging may appear appealing with the right design without spending much money.

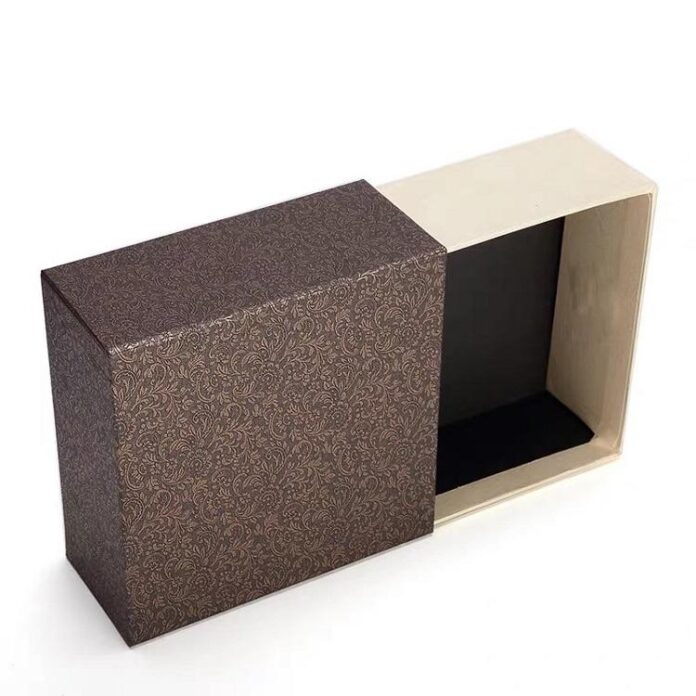

Rigid Boxes

The custom packaging boxes used to package expensive and opulent goods, such as iPhones and Rolex watches, is a rigid or setup box. These boxes look elegant and robust. The box is built of thicker, highly-condensed paperboard than is typically used for folding cartons.

Unsurprisingly, rigid boxes cost more than paperboard and corrugated boxes. Because they are frequently handcrafted and don’t require a large setup of machinery, they are pricey. Additionally, because they are not foldable, they have a larger volume and cost more to ship.

Conclusion

It pays to engage with a business that understands packing and has the expertise and capacity to support you in realizing your shipping goal, whether you’re sending fancy watches, donuts, or everything in between. Industries warmly encourage you to discover more about the full scope of packaging consultancy and fulfillment services they provide.