The textile industry is very large and is evolving every other day. It has grown from hand processing to now the use of technology, not only in the process of making fabric but also in its printing techniques.

What is Textile Printing?

Textile Printing is a process in which color is applied to the fabric in a particular pattern or design. In printed fabrics, the color is tightly bonded with the fabric so that no damage is caused even after washing and friction. It is related to dyeing but the only difference is that in printing you can have more than one color on a single fabric that too in different patterns. Whereas, in dyeing the whole cloth is colored in one single color.

A Beautiful Past

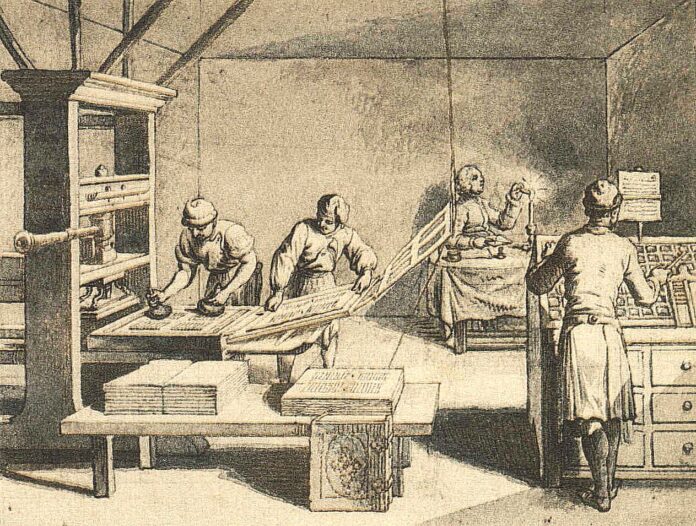

Earlier when the patterns started to leave their impact on clothes, it was done with the help of woodblock printing. It is a technique for printing words, images, or patterns on a piece of fabric. This process was used widely throughout East Asia, and its origins are in China. If we go back to the exact timeline then it is somewhere around 220 when the first cloth was printed. Moreover, besides clothing, many more things such as wall hangings, lectern cloth, and decorative fabrics were also printed in large amounts. At the time when paper became common, technology was rapidly used for woodcut prints. For this superior cloth was imported from Islamic countries, which used to cost just double the actual price of it.

In the early 1630s, the East India Company brought printed and plain cotton fabric, especially for the English market. Soon in the 1660s British printers and dyers started making their printed cotton, in single colors or on plain backgrounds. So that they can sell it in their surroundings although it was less colorful than the imported prints. But it was likable by them as they preferred subtle shades rather than bright colors which were available in the imported stock. Soon, many dye houses started to open in every other city.

Types of Printing Techniques

Hand Block Printing

It is the earliest, simplest, and slowest process in printing. In this, a design is drawn or transferred onto a wooden block and then the further steps are done. For each different color, a different block is used. The wooden block is made in such a way that the cutter carves out the wood around the heavier masses first. Then leaving the finer and more delicate work until the last to avoid any type of risk while the coarser parts are cut out. It is very time-consuming, and these days it is very rare to find intricate designs hand block printed fabric. But to achieve defined designs on a particular piece will only be possible with this method.

Parroting printing

It is also a block printing method, which was named after a machine perrotine. This machine was invented by Perrot of Rouen in 1834. Moreover, it was the only successful machine used for block printing. But now it is all a part of history, now it can’t be found anywhere.

Roller, Cylinder, or Machine Printing

This process was made patented by Thomas Bell, in the year 1785. In this, the machine could print six colors at a time. But there were some flaws due to which it was not that successful. To attain one single color was easy, but the problem came when the five other rollers were filled with colors. As it was hard to adjust them in one single line to have the perfect design. But soon this flaw was corrected by Adam Parkinson in the year 1785.

Screen Printing

Currently, it is one of the most common technology. In this there are two types, one is rotary screen printing and the other is flat screen printing.

Digital Textile Printing

Digital textile printing is also referred to as direct-to-garment printing, also known as DTG printing, or digital garment printing. It is a process of printing on fabrics with inkjet technology. With this process, manufacturers can produce specialized products made for direct printing, not only for sampling but for bulk production.

These were some of the printing techniques which were used in earlier times as well as some new ones, except this there are many other ways to print a piece of fabric.

Have Your Customized Printed Fabric

Sometimes, it might get difficult to find your favorite designs printed in the market. For that, you can get customization on fabrics, in any design, pattern, or color you want. And you can have this at Fabriclore, here along with customization, you will get various prints and patterns. Amongst these designs, you can have an idea, and make your apparel according to them for your next collection. Because to stay up in the list of trendy fabrics customization is the only way to look unique. Not only this, but all certified fabrics that are sustainable and durable are also available so that even after several washes you can have your garment look as new as its first-time look. And don’t worry if you are sitting miles away, because along with India our safe shipping services are available in the US, UK, and Canada.